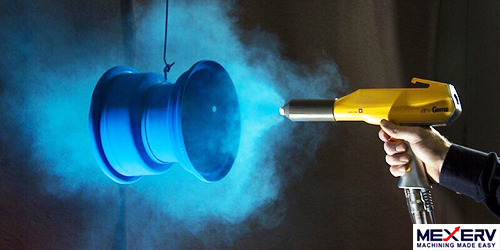

Powder Coating

Powder coating is a commonly applied in the form of a free-flowing, dry powder. Liquid paint is sprayed with an evaporating solvent as opposed to powder coating which is applied by electrostatic means and then allowed to cure under heat or with ultraviolet light. Powder used maybe a thermoplastic or thermoset powder.

Types

- Thermosets powder coating

- Thermoplastics powder coating

- UV curable powder coating

Specifications

| Thermosets | Thermoplastics |

|---|---|

| It is capable of withstanding high temperatures | Could soften/melt if subjected to high temperatures |

| It cannot be remelted, reformed, and recycled | It can be remelted, reformed, and recycled |

| Provides higher scratch and mar resistance | Higher impact resistance is shown. |

| Brittleness is observed (especially in thick coatings) | Flexible in thick coatings |

| Requires a cure cycle to harden | No cure cycle required for hardening |

| Irreversible chemical reaction takes place | No chemical changes. |

Powder Coating is usually used to create a hard finish which is tougher and more wear resistant than regular paint. Powder coating is mainly used for coating of metals, such as household appliances, aluminium extrusions, drum hardware etc.

Advantage

- Powder coatings produce much thicker coatings than liquid coatings without the problem of running or sagging.

- Since powder coatings contain no solvents, they release little or no amount of volatile organic compounds into the atmosphere.

- Powder coated items normally have fewer differences in appearance than liquid coated items in both horizontally and vertically coated surfaces.

- Speciality effects are easily obtained using powder coatings.

- Powder Coatings are environmentally friendly and very cost-effective.